Surface finish: Copper/Tin Plating

Place of Origin:Zhejiang, China

Brand Name:RONCAN

Features: good lubricating and corrosion resistance property

MATERIAL STRUCTURE | |

| Basic characteristics |

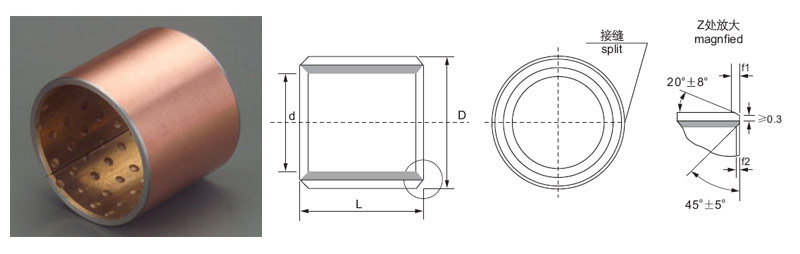

RCB-80 Bimetallic bushings are produced using high-quality composite material, low carbon steel and sintered lead-bronze alloy (CUSN6ZN6PB3) LIKE SAE797/GLYC066/JIS-LBC3, which can stand high sliding rates and has high loading capacity, high resistance to tensile stresses and low coefficient of friction. Due to these properties, bimetallic bushings are widely used in: petrol engines, diesel-oil engines, industrial machinery, lifting apparatus, air conditioners, motor-vehicles gearboxes, reduction gears, laminated springs and heavy vehicles stabilizers. The bushings dimensions (inches or metric system) are in agreement with standards DIN 1494/ISO 3547.International Code like BIV-MET, BMT BIMETAL TYPE1,MSP,SWPB,SJ Series. The product has the advantages of good wear resistance. Especially suitable for medium speed medium load and low speed high load. Through special technology, various oil grooves, oil cavities and oil holes can be machined on the friction surface, so as to adapt to the use under different lubrication conditions. | |

TECHNICAL DATE | ||||

Max.Load | Static | 0N/mm2 | Hardness | HB 70-110 |

Dynamic | 60N/mm2 | Elongation | 10% | |

Max.Speed | 5m/s | Temp. | -40℃~+250℃ | |

Max.PV N/mm2.m/s | Grease Lubrication | 2.8 | Friction coefficient | 0.06~0.14 |

Oil Lubrication | 20 | |||

d | D | Shaft | Housing H7 | Fixed | Thickness | Oil hole | f1 | f2 | L 0-0.40 | ||||||||

max | min | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | ||||||||

10 | 12 | 10-0.022 | 12+0.018 | +0.148 | 0.995 | 0.935 | 4 | 0.5 | 0.3 | 1010 | 1015 | 1020 | |||||

12 | 14 | 12-0.027 | 14+0.018 | 1210 | 1215 | 1220 | |||||||||||

14 | 16 | 14-0.027 | 16+0.018 | 1410 | 1415 | 1420 | |||||||||||

15 | 17 | 15-0.027 | 17+0.018 | 1510 | 1515 | 1520 | |||||||||||

16 | 18 | 16-0.027 | 18+0.018 | 0.8 | 0.4 | 1610 | 1615 | 1620 | |||||||||

18 | 20 | 18-0.027 | 20+0.021 | +0.151 | 1810 | 1815 | 1820 | 1825 | |||||||||

20 | 23 | 20-0.033 | 23+0.021 | +0.181 | 1.490 | 1.430 | 2010 | 2015 | 2020 | 2025 | |||||||

22 | 25 | 22-0.033 | 25+0.021 | 6 | 2210 | 2215 | 2220 | 2225 | |||||||||

24 | 27 | 24-0.033 | 27+0.021 |

| 0.5 | 2410 | 2415 | 2420 | 2425 | 2430 | |||||||

25 | 28 | 25-0.033 | 28+0.021 | 2515 | 2520 | 2525 | 2530 | ||||||||||

26 | 30 | 26-0.033 | 30+0.021 | +0.205 | 1.980 | 1.920 | 2615 | 2620 | 2625 | 2630 | |||||||

28 | 32 | 28-0.033 | 32+0.025 | 2815 | 2820 | 2825 | 2830 | 2840 | |||||||||

30 | 34 | 30-0.033 | 34+0.025 | 1.2 | 0.6 | 3015 | 3020 | 3025 | 3030 | 3040 | |||||||

32 | 36 | 32-0.039 | 36+0.025 | 3215 | 3220 | 3225 | 3230 | 3240 | |||||||||

35 | 39 | 35-0.039 | 39+0.025 | 3520 | 3525 | 3530 | 3540 | 3550 | |||||||||

38 | 42 | 38-0.039 | 42+0.025 | 8 | 3820 | 3825 | 3830 | 3840 | 3850 | ||||||||

40 | 44 | 40-0.039 | 44+0.025 | 4020 | 4025 | 4030 | 4040 | 4050 | |||||||||

d | D | Shaft | Housing H7 | Fixed | Thickness | Oil hole | f1 | f2 | L 0-0.40 | ||||||||

max | min | 25 | 30 | 40 | 50 | 60 | 80 | 90 | 100 | ||||||||

45 | 50 | 45-0.039 | 50+0.025 | +0.205 | 2.460 | 2.400 | 8 | 1.5 | 1.0 | 4525 | 4530 | 4540 | 4550 | ||||

50 | 55 | 50-0.039 | 55+0.030 | +0.210 | 5030 | 5040 | 5050 | 5060 | |||||||||

55 | 60 | 55-0.046 | 60+0.030 | 5530 | 5540 | 5550 | 5560 | ||||||||||

60 | 65 | 60-0.046 | 65+0.030 | 6030 | 6040 | 6050 | 6060 | ||||||||||

65 | 70 | 65-0.046 | 70+0.030 | 6530 | 6540 | 6550 | 6560 | ||||||||||

70 | 75 | 70-0.046 | 75+0.030 | 7030 | 7040 | 7050 | 7060 | 7080 | |||||||||

75 | 80 | 75-0.046 | 80+0.030 | 9.5 | 7530 | 7540 | 7550 | 7560 | |||||||||

80 | 85 | 80-0.046 | 85+0.035 | +0.215 | 8040 | 8050 | 8060 | 8080 | |||||||||

85 | 90 | 85-0.054 | 90+0.035 | 8530 | 8550 | 8560 | 8580 | 85100 | |||||||||

90 | 95 | 90-0.054 | 95+0.035 | 9050 | 9060 | 9080 | 90100 | ||||||||||

95 | 100 | 95-0.054 | 100+0.035 | 9560 | 9580 | 9590 | 95100 | ||||||||||

100 | 105 | 100-0.054 | 105+0.035 | 10060 | 10080 | 10090 | 100100 | ||||||||||

105 | 110 | 105-0.054 | 110+0.035 | 10560 | 10580 | 105100 | |||||||||||

110 | 115 | 110-0.054 | 115+0.035 | 11060 | 11080 | 110100 | |||||||||||

115 | 120 | 115-0.054 | 120+0.035 | 11550 | 11580 | ||||||||||||

120 | 125 | 120-0.054 | 125+0.040 | +0.220 | 12050 | 12060 | 120100 | ||||||||||

125 | 130 | 125-0.063 | 130+0.040 | 125100 | |||||||||||||

130 | 135 | 130-0.063 | 135+0.040 | 13060 | 130100 | ||||||||||||

135 | 140 | 135-0.063 | 140+0.040 | 13560 | 13580 | ||||||||||||

140 | 145 | 140-0.063 | 145+0.040 | 14060 | 14080 | 140100 | |||||||||||

150 | 155 | 150-0.063 | 155+0.040 | 15060 | 15080 | 150100 | |||||||||||